Description

Model ISG single-stage single-suction vertical centrifugal pump is a high-effective energy-saving product successfully designed by means of adopting the property data of IS model centrifugal pump and the unique merits of vertical pump and strictly in accordance with ISO2858 world standard and the latest national standard and an ideal product to replace IS horizontal pump, DL model pump etc. ordinary pumps.

The flow range is 1.5 2400m /h and the stroke range38-150m and there are basic type, by-passtype, A B C cutting type etc. more than 250 specifications. And per the different flow medium and temperature, IRG hot-water pump, IHG chemical pump and YG oil pump and IHGB vertical non-explosive chemical pump. etc. Series products. of the same type and same proprty data have been designed and made.

Features

● Compact structure, small volume, beautiful outlook.

The lower center of the vertical structure which coincides with the center of the pump feet strengthens the stability of running and the duration.

● Easy to mount.

Because of the same apertures of both inlet and outlet which also locate on the same central line, the pump can be directly mounted on any part of the pipeline just as a valve. The motor is covered with a rainproof cap so that operation can be done outdoors. Mounting feet are equipped with the pump so that it can be stably mounted.

● Stable running, low noise, high concentric of components.

Bearings of low noise are used for the motor, the impellers are of best dynamic and static balance, no vibration at running and the environment thus being improved.

● No leakage.

The shaft is mechanically sealed with carbide alloy wearable material, settling the serious leakage of the filling seal of a centrifugal pump, extending the duration and ensuring the operation place clean and tidy.

● Easy to maintain.

Not necessary to remove the pipeline for check-out and maintenance, only to take out

the nuts on the pump lid, the motor and the driving components.

● Multiple installation modes.

The pump, according to the operation condition of the work site, may be vertically, horizontally etc. multi ways mounted and also according to the requirements for the flow and stroke, mounted in parallel and/or in series to increase the needed flow and stroke.

Working Conditions

● Working pressure

Max.working pressure of pump system is 1.6 MPa, that is to say the pressure at the suction+the stroke 1.6 MPa,the pressure in static tests is 2.5 MPa, please notify the pressure for the system at work when ordering and it should be otherwise noted of the said pressure is larger than 1.6 MPa so as to use cast steel material for the overflow and joint parts.

● Proper medium

The medium for pure water pumps should have no corrosive liquid and the volume of non-melting medium solid should not be over 0.1% of the unit volume and the graininess less than 0.2 mm. Please notify at order if the medium to be used with small grain.

● Environmental conditions

No larger than 40 of the ambient temperature, no higher than 1000 m of the above-sea level and no more than 95% of the relative humidity

Application

● ISG series vertical centrifugal pump is used to transport pure-water and other liquids, the physical properties of

which are similar to those of pure-water,in industrial and cities'water supply

and drainage, high buildings' booster water supply, gardens irrigation,

fire-fighting booster, remote water supply, warming systems, circular booster

of cold&hot water in bath rooms as well as in completions of equipment, the

operation medium temperature is below 80℃.

● IRG

series vertical hot-water pump is used for the warming

hot-water booster circular system and the heat transport system of production

technology in the units where heat-supply systems are available, such as the

power station, thermal power station, residual utilization, metallurgy, chemistry,

textile, wood-processing, paper-making etc. industrial boilers' high-temperature

hot-water,the operation temperature is below 120℃.

● IHG

series vertical chemical pump is used to transport the

liquids containing no solid grain, corrosive and the viscosity of which is

similar to water or the departments of light&textile industry, petroleum,

chemical industry, metallurgy, electricity, paper-making, marine sea water, food, medicine and synthetic etc.,the operation

temperature is -20~120℃.

● YG

series vertical non-explosive oil pump is used to light&textile, chemical, mechanical etc., industries to

transport non-corrosive, flammable, explosive liquids, the medium temperature

is -20~120℃

and density less than 1000 kg/m³.

● IHGB

series vertical non-explosive chemical pump is used to transport the liquids containing no solid grain, corrosive and the

viscosity of which is similar to water for the department of light&textile

industry, petroleum, chemical industry, metallurgical industry, mining,

medicine and synthetic fiber etc. the operation temperature is -20~120℃ .

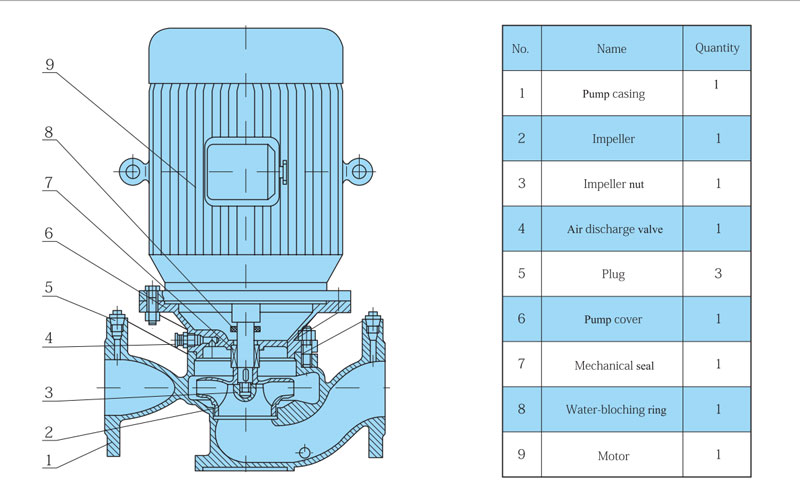

Structure Description