How to Optimize Pump Performance in Harsh Conditions?

Industrial pumps face brutal challenges—scorching temperatures, corrosive chemicals, and abrasive slurries can slash efficiency by 40% and trigger costly downtime. But what if your pumps could not just survive but thrive in these extremes?

Harsh environments demand engineered resilience: Material science, precision design, and predictive maintenance are your frontline weapons.

While 72% of pump failures in extreme conditions trace back to material fatigue or design mismatches, the solution lies in a holistic strategy. Let's dissect three pillars to transform pump reliability—even when operating at 500°C or submerged in sulfuric acid.

How Do You Select Pump Materials That Outlast Corrosion and Abrasion?

Material choice isn't a checkbox—it's a survival calculus. A single misstep here can cascade into catastrophic failures, like the 2023 Texas refinery incident where chloride stress corrosion cracked stainless steel pumps within 6 months.

Forget generic alloys: Target material properties that align with your specific threats—whether it's HCl vapors or silica-laden slurries.

| Threat | Material Champion | Real-World Edge |

|---|---|---|

| 400°C+ Thermal Shock | Inconel 625 (Ni-Cr-Mo) | Withstands thermal cycling in LNG liquefaction pumps |

| 50% Sulfuric Acid | Zirconium (Zr702) | Zero corrosion in chemical transfer after 5+ years |

| 30% Abrasive Solids | Tungsten Carbide Lining | Slashes wear rates by 90% in mining tailings |

Pro Tip: Partner with metallurgists to simulate your exact operating conditions—pH, ppm contaminants, and peak temperatures—in material test rigs.

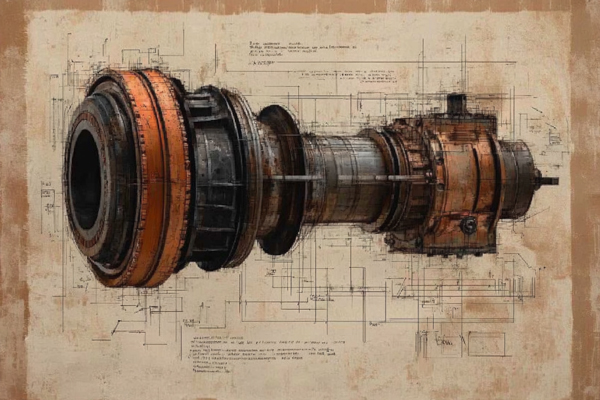

Can Smart Pump Design Turn Extreme Conditions into an Advantage?

Design isn't just about specs; it's about anticipating failure modes. A well-designed pump for geothermal brine (180°C, H₂S-rich) isn't a tweaked standard model—it's a purpose-built system with redundancies.

Engineer backward from the harshest scenario: If your fluid contains 15mm particulates, design seals and impellers to handle impacts, not just flow rates.

Sealing Systems: Double mechanical seals with API Plan 23 flush prevent clogging in polymer melts

Hydraulic Profile: CFD-optimized impellers reduce cavitation damage in seawater desalination pumps

Cooling Jackets: Built-in titanium channels maintain <80°C casing temps in 300°C hydrocarbon duties

Case Study: A copper mine boosted slurry pump life by 300% using 3D-printed impellers with erosion-resistant lattice structures.

Is Your Maintenance Strategy Fighting Symptoms—Or Preventing Failures?

Reactive maintenance in harsh conditions is like fixing leaks on a sinking ship. The real game-changer? Predictive analytics that spots bearing wear or seal degradation weeks before failure.

Swap wrench time for AI insights: Vibration sensors and fluid debris monitors predict failures with 92% accuracy.

IoT Sensors: Track real-time parameters (e.g., 4-20mA vibration signals) against ISO 10816 limits

Oil Analysis: Detect Fe/Ni wear particles >20µm to schedule bearing replacements proactively

Laser Alignment: Correct misalignment within 0.05mm to prevent shaft fractures in high-torque pumps

Data Point: Shell's Pernis refinery cut unplanned downtime by 65% using cloud-based pump health algorithms.

Conclusion: Engineering Pumps That Embrace the Extremes

Optimizing pumps for harsh environments requires a blend of precision engineering and operational pragmatism. At Yaness, we focus on three pillars that align with your real-world needs:

✓ Material Expertise: Our team specifies materials through rigorous field testing

✓ Design Adaptability: Tailored designs matching operational reality

✓ Maintenance Partnerships: Lifecycle cost analysis and preventive strategies

Why Choose Yaness?

Decades of Field Experience: 800+ pump failure scenarios resolved

No-BS Approach: Transparent recommendations without overselling

Rapid Customization: Modify standard geometries within 72 hours

Need a pump that works as hard as your environment does? Contact Yaness for a no-obligation consultation. Send us your fluid specs and pain points—we'll draft a solution within 48 hours.